Echophone Ec 1b Manual Meat

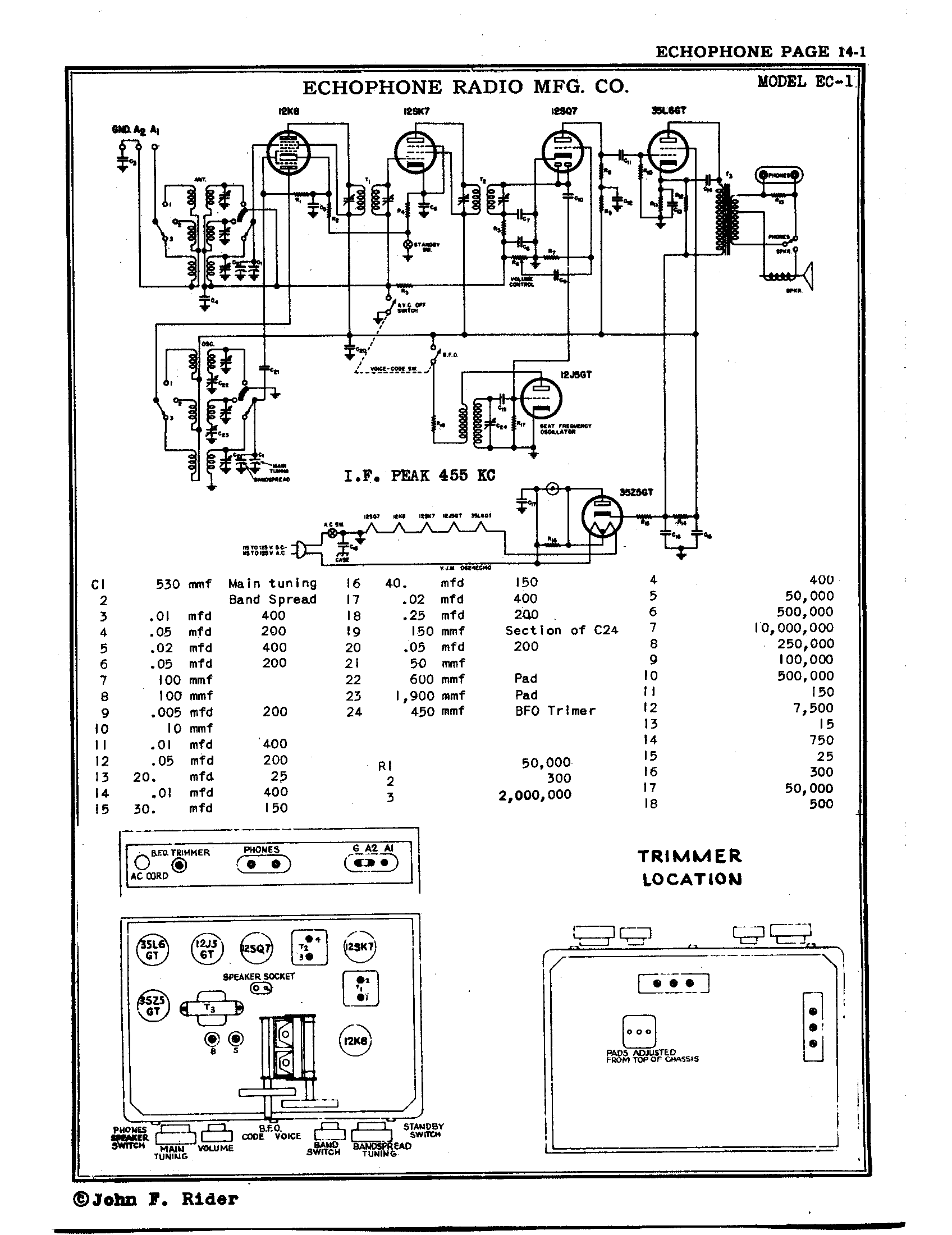

This is either a EC1A or EC1B, but I cannot tell which.According to this site:The EC-1B is nearly identical to model EC-1A. Both are updated versions of the EC-1. The EC-1B uses an inductor link to the oscillator coil for the bandspread with a cheaper broadcast-type variable capacitor. The EC-1A uses the more conventional and more expensive dual-control variable capacitor.And I could use a manual for whichever model this is.ThanksAttachments:Echophone 1.jpg 216.74 KiB Viewed 5083 times Echophone 2.jpg 149.89 KiB Viewed 5083 times Echophone.jpg 144.92 KiB Viewed 5083 times. Chris,Your receiver appears to be the -A version as indicated by the dial; your photo angle is a little difficult to be sure but it appears to have the small bandspread capacitor which interacts with the main capacitor. A straight down shot with the case off would clarify this but I am 99% sure of the model.ON EDIT: Radiomuseum.org has the schematic and I believe non-members are now able to download so you can get the schematic there:I don't have the manual for this one but I expect it is very close to the original Hallicrafters S-38 (not the later letter suffix models) which also had the separate BFO tube for a real BFO. These are pretty simple receivers so you should be fine even if you don't find a perfect manual and schematic.

They are basically a slightly enhanced All American 5 type set, just remember these are AC/DC sets so use proper caution both in servicing and later operation.Rodger WQ9E. Thanks Rodger, I just retrieved the schematic from your link. I also have ordered the various capacitors once I identified them by scraping wax where needed.

There is one 4-way presumably electrolytic, and I ordered those as separates. I almost certainly have all the resistors in case any test out of spec.Once I have swapped the paper caps and tested the resistors, and applied the safer-hot-chassis mod, are there any voltage checks I can make like described on the SX28 docs?

And I wonder about alignment.Should try to use S38 (no suffix) manual? Chris,I can't think of any preparatory voltage checks to make on the your Echophone (or most AC/DC sets).

Replace the capacitors, make sure that the proper tubes are in the sockets, add a fuse, and you are ready to test. Brahms complete edition flac files. The alignment of these simple sets is straightforward but if at all possible use an isolation transformer at your bench during alignment.

They aren't expensive and are useful for anyone who does any significant amount of work on older radios. Even if you modify this one to reduce the risks from a line operated set the day will come when a friend or relative will ask you to take a quick look at their AA5 or some similar family heirloom and it would be best for you and your test gear to be able to plug the little beast into an isolation transformer.Rodger WQ9E. Thanks as always Rodge, I did buy a Viz Isotap Isolation Transformer and it is at my bench at all times.

The entire 'lab' (boiler closet) is on a GFCI circuit, FWIW. The only thing I should really add is a rubber mat, come to think of it. Also, for others who may read this NO amount of equippage can make electricity safe. If I were to touch voltage with one hand, and return with the other, the 'safety' gear will think I am a normal load and not do anything.

And lets just say I know that for a fact. OK, replaced most caps (the.01,.o2, and.05 which I had on hand) just have to wait for a couple values to come in the mail. This part is easy, since they are individual, and marked.HOWEVER, after finding a clear S38 schematic identical to the radio museum one but clearer, the electrolytic 4 way cap does not match anything I can find.This is so frustrating. I tried working backwards, frontwards, and following the schematic.Here's what I have of the four leads in case anyone sees this who has repaired an EC1A:Blue: goes to Tube 4, Pin 8Red: Tube 6 Pin 6Whitish (hard to tell): Tube 4 Pin 4Whitish (again hard to tell): Center Tab of a term strip then Tube 1 Pin 4The values are 40-30-30-20Just dont know which is what. Dave thanks, thats one (of four) down I can easily now run that pin into the positive side of a electrolytic (right?) and the other caps lead to chassis.rodger, as to your EC1A and B variable tuning capacitor question, and S41G vs S38 schematic, here is a top pic of the main metal plate tuning capacitor. It appears to have two sections, identifying this unit as an 'A model'.The ohio state page says posted earlier above) that the EC1B is matched by the S41G schematic while you've matched the A model to S38.

These are hard enough to read but to crystal clarify this, the ohio.edu page describes a single tuning cap with different method of slug inside coil for a bandspread, so the schematic cannot be exactly the same.This would be good to clarify for future amateur EC1A/B owners who are 'more interested than familiar' with this topic.EC1A = uses dual variable tuning capacitor - use S38 schematicEC1B = uses single variable tuning capacitor, bandspread via slug/coil - use S41G schematiccorrect?when I get time I will look myself at both. (again things like tube pin numbers and component value numbers can be hard or impossible to read.)Attachments:varicap ec1.jpg 235.61 KiB Viewed 4988 times Last edited by on Aug Wed 24, 2016 2:04 am, edited 2 times in total. Chris,That is a pretty typical low cost dual variable cap setup used in a number of Hallicrafters receivers where it adds a second rotor shaft with limited plates that interact with the main capacitor stator plates.When it comes to Hallicrafters build vs schematic there are no hard and fast rules. There are numerous disconnects between build vs schematic for many models as 'documented' on the internet and you can be confident not all variants have been discovered or documented. The best way to approach this problem is to treat it as a great learning opportunity where you improve your abilities to discover discrepancies between documentation and actual while simultaneously learning more about circuit function. In many cases the best approach is to gather all potentially relevant documentation and figure out if one is exact or (more likely) is your set actually a slight hybrid of different schematics.Sometimes changes were made due to new discoveries, to improve operations, cut costs, or seemingly for no good reason. While repairing or aligning a radio if that little voice in your head cautions you that something isn't quite right then listen to it and drill further down into the schematic and build.

If multiple little voices start arguing about the radio then it is time to update your medsRodger WQ9E. Thanks Michael. I had seen that video but then forgot!

Carlson is a bit annoying but he is articulate and detailed with often-useful info.Here is my latest, cleaned the dusty rusty chassis a bit, and restrung the bandspread. Rodger's point about the bandspread varicap is easy to see, just a couple extra plates into the same metal plate capacitor. Pretty clever!Not sure if I can clean the brown layer off the dial plate. Dish soap and a cloth didnt touch it.Attachments:20106s.jpg 142.62 KiB Viewed 4889 times 20127.jpg 144.29 KiB Viewed 4889 times.

Chris,Be sure to do a good scan before trying anything harsher to clean the dial. Personally I would go with it as it looks now since it is unlikely to clean up perfectly (that tint/tinge is likely from age, heat, and/or contaminants now baked into the paint) and there is a good chance that you could lose part of the lettering or paint during additional cleaning.

Knowing when to stop is one of the most difficult things and most of us (I am certainly guilty) never fully learn it. Too many times I have had radio, woodworking, and mechanical projects that were really quite good but I couldn't resist one more step which resulted in a lot more work and a final product that still wasn't as good as it was prior to that ill-advised final step.The chassis looks much better after your work on it!Rodger WQ9E. Hi Rodge thanks, yes I stopped when the cloth and soap did absolutely nothing. And when I did try to clean it, was at the very edge. It quickly became apparent that the yellowed coating was bonded pretty well. Even if I could get it off the face, as you indicated, how close could I ever get to the printed black lettering and lines? Figured it would look worse.The electrolytics are now replaced, going to get grommets at Lowes.

Echophone Ec 1b Manual Meatloaf

I installed a 3-wire cloth power cord with neutral to the power switch and ground to the chassis. If a receptical is reversed (and grounded),turning the switch on should trip the breaker. In fact, that reminds me I have some panel fuse holders, may install one of those.Can run this on the isolation transformer for now to test. Then try and find some info on alignment IF it works. BTW I have not yet tested all the resistors, doing them here and there they have been fairly close to spec.

This is either a EC1A or EC1B, but I cannot tell which.According to this site:The EC-1B is nearly identical to model EC-1A. Both are updated versions of the EC-1.

The EC-1B uses an inductor link to the oscillator coil for the bandspread with a cheaper broadcast-type variable capacitor. The EC-1A uses the more conventional and more expensive dual-control variable capacitor.And I could use a manual for whichever model this is.ThanksAttachments:Echophone 1.jpg 216.74 KiB Viewed 5083 times Echophone 2.jpg 149.89 KiB Viewed 5083 times Echophone.jpg 144.92 KiB Viewed 5083 times. Chris,Your receiver appears to be the -A version as indicated by the dial; your photo angle is a little difficult to be sure but it appears to have the small bandspread capacitor which interacts with the main capacitor.

A straight down shot with the case off would clarify this but I am 99% sure of the model.ON EDIT: Radiomuseum.org has the schematic and I believe non-members are now able to download so you can get the schematic there:I don't have the manual for this one but I expect it is very close to the original Hallicrafters S-38 (not the later letter suffix models) which also had the separate BFO tube for a real BFO. These are pretty simple receivers so you should be fine even if you don't find a perfect manual and schematic.

They are basically a slightly enhanced All American 5 type set, just remember these are AC/DC sets so use proper caution both in servicing and later operation.Rodger WQ9E. Thanks Rodger, I just retrieved the schematic from your link.

I also have ordered the various capacitors once I identified them by scraping wax where needed. There is one 4-way presumably electrolytic, and I ordered those as separates. I almost certainly have all the resistors in case any test out of spec.Once I have swapped the paper caps and tested the resistors, and applied the safer-hot-chassis mod, are there any voltage checks I can make like described on the SX28 docs? And I wonder about alignment.Should try to use S38 (no suffix) manual?

Chris,I can't think of any preparatory voltage checks to make on the your Echophone (or most AC/DC sets). Replace the capacitors, make sure that the proper tubes are in the sockets, add a fuse, and you are ready to test. The alignment of these simple sets is straightforward but if at all possible use an isolation transformer at your bench during alignment. They aren't expensive and are useful for anyone who does any significant amount of work on older radios. Even if you modify this one to reduce the risks from a line operated set the day will come when a friend or relative will ask you to take a quick look at their AA5 or some similar family heirloom and it would be best for you and your test gear to be able to plug the little beast into an isolation transformer.Rodger WQ9E.

Thanks as always Rodge, I did buy a Viz Isotap Isolation Transformer and it is at my bench at all times. The entire 'lab' (boiler closet) is on a GFCI circuit, FWIW. The only thing I should really add is a rubber mat, come to think of it. Also, for others who may read this NO amount of equippage can make electricity safe. If I were to touch voltage with one hand, and return with the other, the 'safety' gear will think I am a normal load and not do anything. And lets just say I know that for a fact. OK, replaced most caps (the.01,.o2, and.05 which I had on hand) just have to wait for a couple values to come in the mail.

This part is easy, since they are individual, and marked.HOWEVER, after finding a clear S38 schematic identical to the radio museum one but clearer, the electrolytic 4 way cap does not match anything I can find.This is so frustrating. I tried working backwards, frontwards, and following the schematic.Here's what I have of the four leads in case anyone sees this who has repaired an EC1A:Blue: goes to Tube 4, Pin 8Red: Tube 6 Pin 6Whitish (hard to tell): Tube 4 Pin 4Whitish (again hard to tell): Center Tab of a term strip then Tube 1 Pin 4The values are 40-30-30-20Just dont know which is what. Dave thanks, thats one (of four) down I can easily now run that pin into the positive side of a electrolytic (right?) and the other caps lead to chassis.rodger, as to your EC1A and B variable tuning capacitor question, and S41G vs S38 schematic, here is a top pic of the main metal plate tuning capacitor. It appears to have two sections, identifying this unit as an 'A model'.The ohio state page says posted earlier above) that the EC1B is matched by the S41G schematic while you've matched the A model to S38. These are hard enough to read but to crystal clarify this, the ohio.edu page describes a single tuning cap with different method of slug inside coil for a bandspread, so the schematic cannot be exactly the same.This would be good to clarify for future amateur EC1A/B owners who are 'more interested than familiar' with this topic.EC1A = uses dual variable tuning capacitor - use S38 schematicEC1B = uses single variable tuning capacitor, bandspread via slug/coil - use S41G schematiccorrect?when I get time I will look myself at both. (again things like tube pin numbers and component value numbers can be hard or impossible to read.)Attachments:varicap ec1.jpg 235.61 KiB Viewed 4988 times Last edited by on Aug Wed 24, 2016 2:04 am, edited 2 times in total. Chris,That is a pretty typical low cost dual variable cap setup used in a number of Hallicrafters receivers where it adds a second rotor shaft with limited plates that interact with the main capacitor stator plates.When it comes to Hallicrafters build vs schematic there are no hard and fast rules.

There are numerous disconnects between build vs schematic for many models as 'documented' on the internet and you can be confident not all variants have been discovered or documented. The best way to approach this problem is to treat it as a great learning opportunity where you improve your abilities to discover discrepancies between documentation and actual while simultaneously learning more about circuit function. In many cases the best approach is to gather all potentially relevant documentation and figure out if one is exact or (more likely) is your set actually a slight hybrid of different schematics.Sometimes changes were made due to new discoveries, to improve operations, cut costs, or seemingly for no good reason. While repairing or aligning a radio if that little voice in your head cautions you that something isn't quite right then listen to it and drill further down into the schematic and build. If multiple little voices start arguing about the radio then it is time to update your medsRodger WQ9E. Thanks Michael. I had seen that video but then forgot!

Carlson is a bit annoying but he is articulate and detailed with often-useful info.Here is my latest, cleaned the dusty rusty chassis a bit, and restrung the bandspread. Rodger's point about the bandspread varicap is easy to see, just a couple extra plates into the same metal plate capacitor. Pretty clever!Not sure if I can clean the brown layer off the dial plate. Dish soap and a cloth didnt touch it.Attachments:20106s.jpg 142.62 KiB Viewed 4889 times 20127.jpg 144.29 KiB Viewed 4889 times.

Chris,Be sure to do a good scan before trying anything harsher to clean the dial. Personally I would go with it as it looks now since it is unlikely to clean up perfectly (that tint/tinge is likely from age, heat, and/or contaminants now baked into the paint) and there is a good chance that you could lose part of the lettering or paint during additional cleaning. Knowing when to stop is one of the most difficult things and most of us (I am certainly guilty) never fully learn it.

Too many times I have had radio, woodworking, and mechanical projects that were really quite good but I couldn't resist one more step which resulted in a lot more work and a final product that still wasn't as good as it was prior to that ill-advised final step.The chassis looks much better after your work on it!Rodger WQ9E. Hi Rodge thanks, yes I stopped when the cloth and soap did absolutely nothing. And when I did try to clean it, was at the very edge. It quickly became apparent that the yellowed coating was bonded pretty well. Even if I could get it off the face, as you indicated, how close could I ever get to the printed black lettering and lines?

Figured it would look worse.The electrolytics are now replaced, going to get grommets at Lowes. I installed a 3-wire cloth power cord with neutral to the power switch and ground to the chassis. If a receptical is reversed (and grounded),turning the switch on should trip the breaker. In fact, that reminds me I have some panel fuse holders, may install one of those.Can run this on the isolation transformer for now to test. Then try and find some info on alignment IF it works. BTW I have not yet tested all the resistors, doing them here and there they have been fairly close to spec.